Milling machine

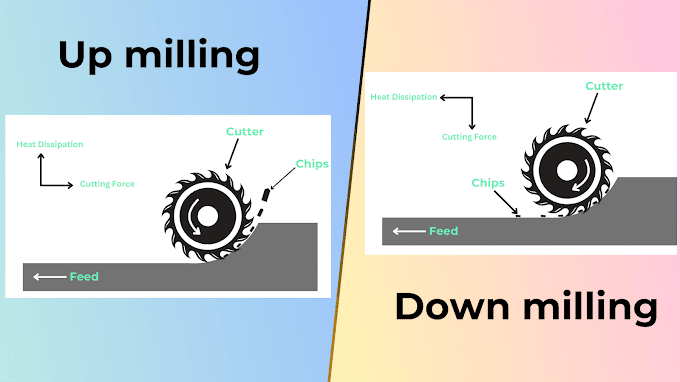

What is up milling and down milling?

1. Up milling

- In up milling cutter are rotating against direction of workpiece move in order to removal of material.

- Chip thickness is minimum at start and is so tight that cutter has a tendency to slide over work untill suffiecient pressure.

2. Down milling

- In Down milling cutter and workpiece moved in same direction in order to remove material from workpiece surfaces.

- From the starting of operation cutter is fully engage hence resulting in better finishing.

What is milling operation?

What is the main function of milling machine?

Plain or dlab milling:

It is an most common milling process which used for removing material from plan, flate, horizontal plate. It's also known as slab milling.

Face milling:

In face milling face cutter rotates perpendicular to the workpiece.

End milling :

Side milling : in this milling process side milling cutter are most times used to adjust side of workpiece.

Slot milling :

Angular milling this milling process is used to done angular surface. This angle is may be single or double.

Form milling:

This milling is mainly used to cut in irregular shape like concVe or convex surface.

What are the different types of milling machines?

1. Column and Knee Type

a) Hand Milling Machine

c) Vertical Milling Machine

d) Universal Milling Machine

e) Omniversal Milling Machine

2.Manufacturing Type or Fixed Bed Type Milling Machine

a) Simplex Milling Machine

b) Duplex Milling Machine

c) Triplex Milling Machine

3.Planer Type Milling Machine

4.Special Type Milling Machine

a) Rotary Table Milling Machine

b) Drum Milling Machine

c) Profile Milling Machine

d) Planetary Milling Machine

e) Tracer Control Milling Machine

f) Pentagraph Milling Machine

g) NC/CNC Milling Machine

What is the main parts of milling machine?

1. Base

Base is serves as foundation for all of the structure and its rigid casting structure.

2. Column

Colum is supporting structure which are mounting at one end on base to distribution load of other component to ground via base.

3. Saddle

Saddle is use to provide aligning to the table and saddle is place parallel to the column.

4. Overhanging arm

Its mount on top of the colum face and work of it is to provide support to the arbor.

5. Front brace

Front bace is provide extra support to the arbor.

6. Spindle

Spindle is used to remove material from workpiece by his cutting edge. Spindle is rotate by motor through the clutch, belt or gears transmission.

7. Arbor

Arbor is extension part of machine in order to rotate spindle on his axis.

8. Elevation screw

Its use to provide aliding motion to the table on which workpiece mounted.

How do milling machines work step by step?

Step-1: Setup of workpiece

At the time of starting any milling operation firstly setup the workpiece on table and adjust it as per requirement by the movement of the knee, saddle and arbor in 3 different direction.

Step-2: Clamping of workpiece

after adjusting workpiece on work table next step is to fix this part on table, so it can"t move during process. for clamping there are many ways.

For example many fixture are available to fix the part or clamping instrument available by which we can easily fix on table.

Step-3: Selecting tool

Tool selection is important step in milling operation, because numbers of tools available hence as per operation we have to mount tool on arbor.

Step-4: Performing the operation:

After attaching tool, actual work to be perform on work piece for that operator have to move nobe given in machines as per requirement, in simple words operator have to move the knee, saddle and arbor as per requirement.

What is the axis of a milling machine?

- Basic Millling machine are able to move in 3 axis,in which up and down motion of work table if done by the help of knee and handle which rotate the elevating screw, in this way table can motion verticle.

- Left- right movement are perform by the help of saddle which place perpendicular to column.

- front and back motion in milling machine occur by the help of overhanging arm and arbor on which spindle is mounted.

Read More about CNC machine:

Types of CNC machine: click here

Introduction to CNC machine: click here

advantages of CNC machine: click here

application of CNC machine: click here

Milling machines: click here

Up vs Down milling: Click here

Thank you.